Rectangular lime kiln

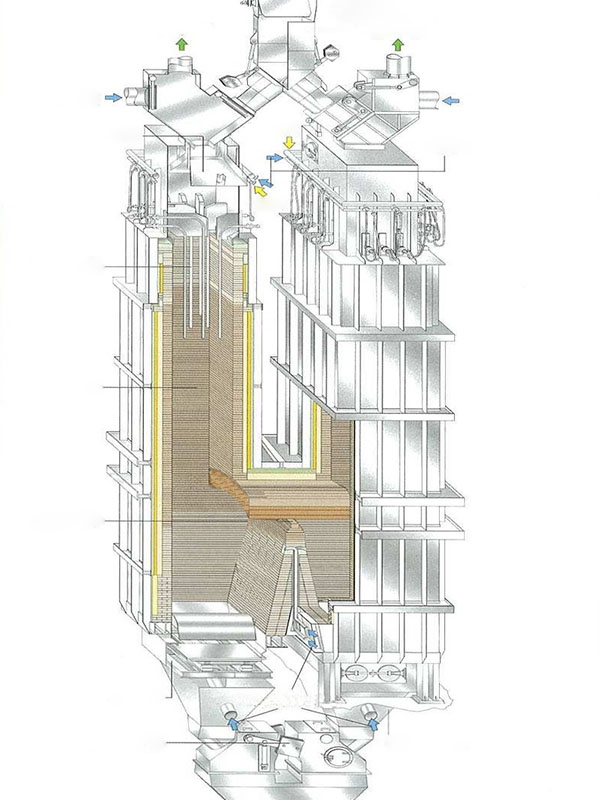

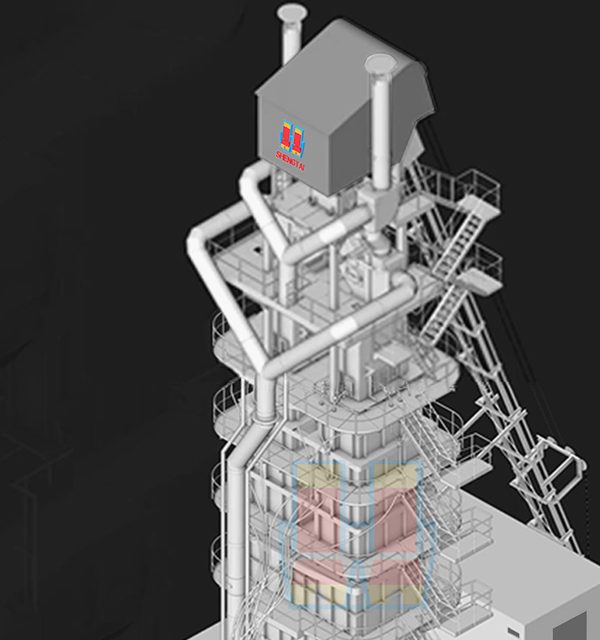

The core design principle of the rectangular double-chamber lime kiln lies in structural simplification: two kiln cylinders with rectangular cross-sections are arranged side by side along the longitudinal direction, and the two kiln cylinders are directly connected through a straight-through channel. The gas inside the kiln can flow directly from one kiln cylinder to the other through this channel, without the need for complex flow-guiding structures.

This simple design brings significant cost and construction advantages: due to the rectangular geometry, the kiln body’s requirements for the load-bearing capacity of the steel structure and the complexity of refractory material laying are greatly reduced. This not only cuts down material costs but also lowers the difficulty of kiln construction, making the construction process easier to advance.

From the perspective of application scenarios, this type of simple and economical kiln is mainly suitable for calcination projects of lime or dolomitic lime, especially meeting the production demand of 400 tons per day.

For kilns with higher daily output, a special flap-type feeding system is equipped — this system can accurately control the particle size distribution of limestone in the kiln cylinder, avoid gas blockage or deflection caused by uneven particle size, ensure uniform gas flow inside the kiln, and provide a key guarantee for the stable production of high-quality lime products.

Current design performance parameters of the rectangular kiln:

Daily output (tons): 80~400

Limestone particle size (mm): 30~120

Fuel: gaseous, liquid and powdered solid fuels

Heat consumption (kilojoules per kilogram of lime produced): approximately 3520

(kilocalories per kilogram of lime produced): approximately 840

Lime activity: very high to medium

As a leading manufacturer in the industrial kiln field, Huixin has always been committed to providing customized services that meet the specific needs of global customers. Relying on advanced rectangular double-chamber kiln technology, we offer comprehensive customized solutions to help customers achieve the best production results and maximum return on investment.