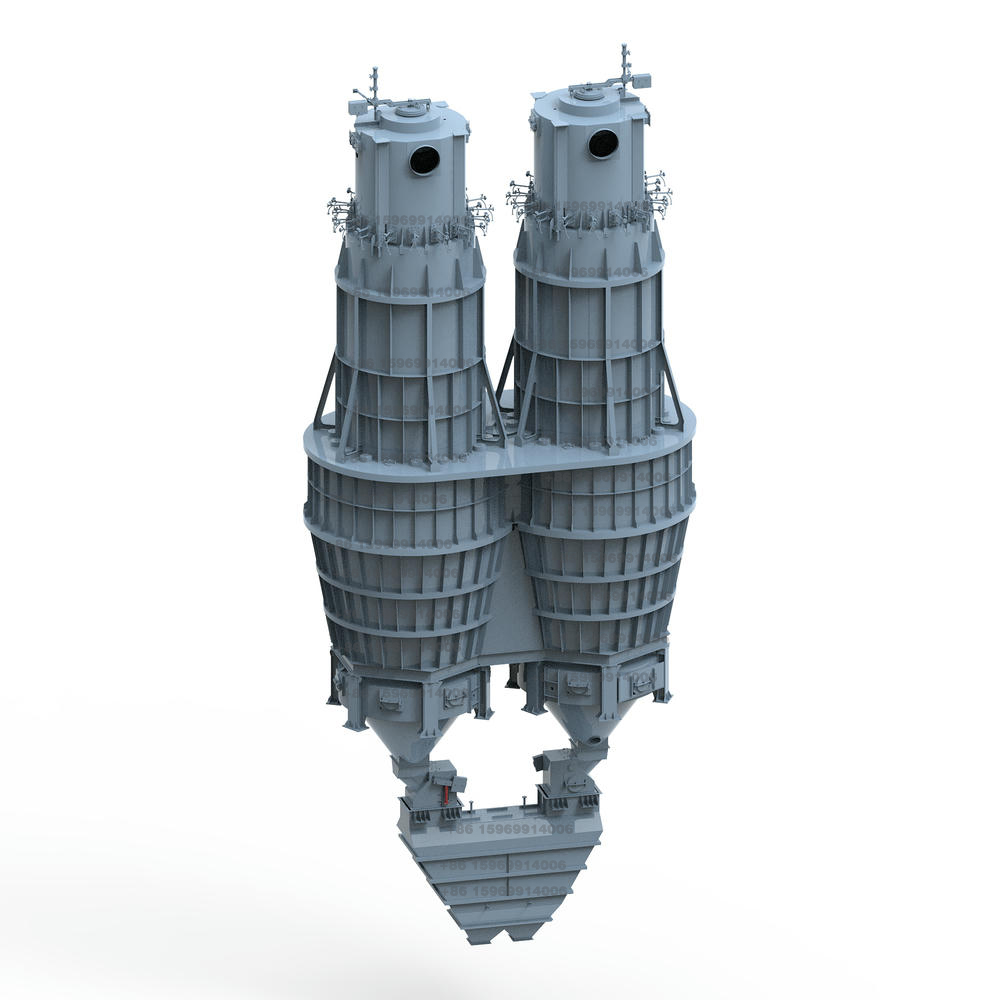

LM-Corbel-Regenerative Shaft lime Kiln Shell Structure-High-efficiency lime kilns

The shaft kiln shell is constructed using steel structures, with the primary functions of ensuring the stability and reliability of the kiln lining, guaranteeing the airtightness of the kiln body, supporting various equipment installed on the kiln, and maintaining the proper progression of the combustion process.

The rationality of the kiln structure directly impacts the quality, output, and service life of the lime. The kiln shell is welded from 10 mm thick steel plates. To ensure structural strength and airtightness, a 16 mm thick hoop reinforcement plate is added at transverse weld joints, while 10 mm thick vertical ribs are installed on the outer surface of the steel plates, with a 12 mm thick steel plate wrapping the intermediate sections. The design accounts for thermal expansion of refractory materials during combustion, as well as outward gas expansion from limestone decomposition, preventing shell cracking or weld failure. For ease of construction and maintenance, multiple manholes and access doors are incorporated at varying heights.

Corbel-Supported Twin-Shaft Kiln

Structure & Features

– Corbel Structure: Multi-layer corbels (cantilevered supports) are installed on the inner kiln walls, forming stepped platforms to distribute and support limestone.

Operation:

– Material descends through corbel layers, interacting with hot gases (counter/parallel flow) for preheating, calcination, and cooling.

– Corbels extend material residence time, improving heat transfer efficiency.

Advantages:

– Suitable for large-sized raw materials .

– Simple structure and low maintenance costs.

– Uniform calcination with high reactivity (≥350mL).

Disadvantages:

– Corbels are prone to thermal wear, requiring periodic replacement.

– Slightly lower thermal efficiency (heat consumption: ~800-900 kcal/kg lime).