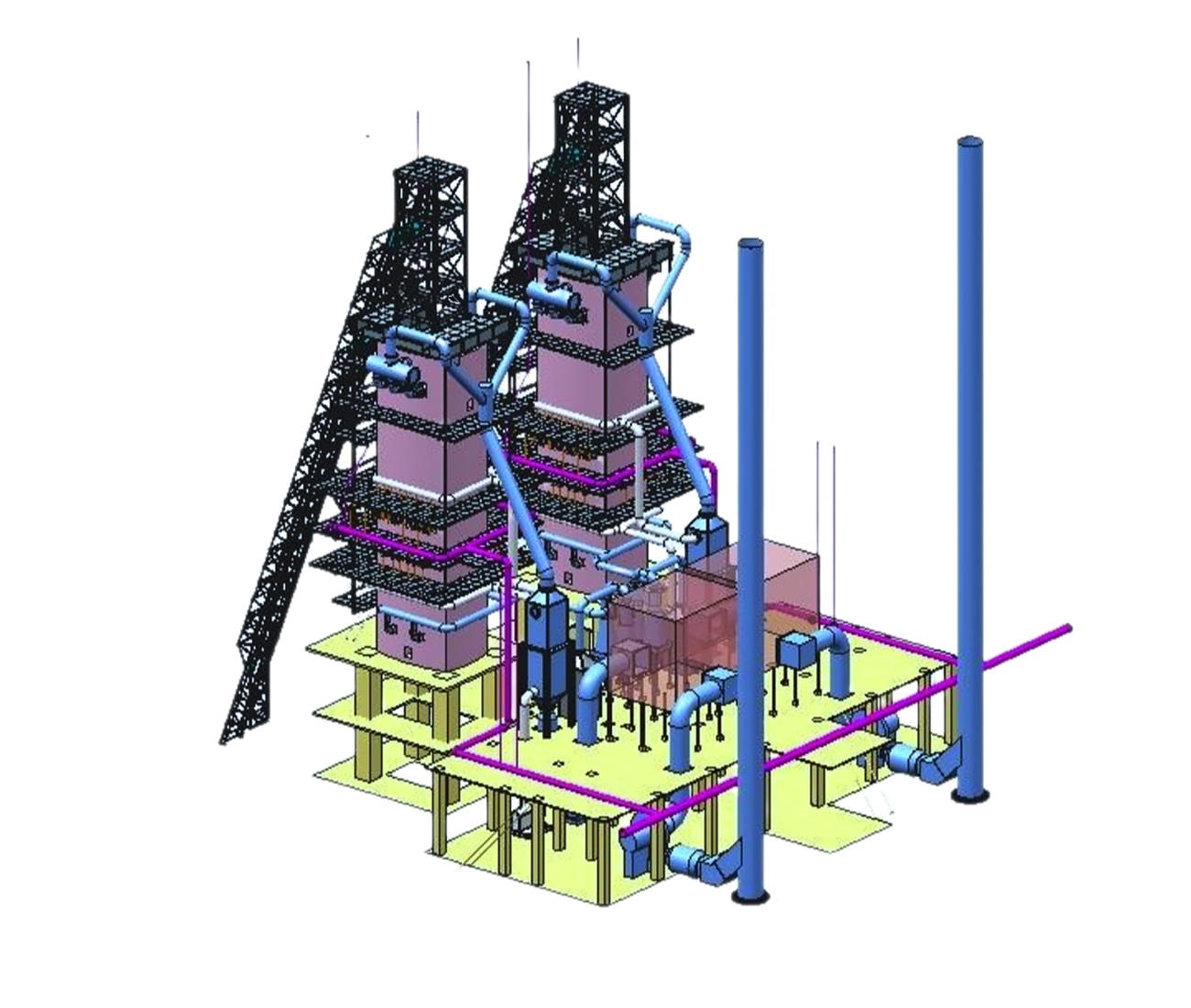

Main Technical Features of Our Company’s Double Beam Lime Kiln

Production Capacity: 100–600 t/d, available in circular or rectangular kiln designs.

Operational Flexibility: The kiln can operate at 70–100% capacity with stable production, without affecting lime quality or consumption indicators.

Multiple Fuel Options: Compatible with pulverized coal, calcium carbide furnace gas, natural gas, coke oven gas, mixed gas, blast furnace gas (calorific value ≥750 kcal/m³), or a combination of pulverized coal and gas.

Low Heat Consumption & Efficient Energy Utilization: Secondary air preheats the lime during cooling, while primary air is preheated through the preheater and enters the combustion beam, ensuring complete fuel combustion and optimal heat utilization.

Fuel Adaptability: For low-calorific fuels, both air and gas are preheated; for high-calorific fuels, only air is preheated.

Enhanced Combustion System for Low-Calorific Fuels: In addition to the original double-layer burner beam, a peripheral combustion system is installed to optimize the calcination cross-section.

Precise Combustion Control: Each burner is responsible for calcining its own unit and can be independently controlled, ensuring complete gas combustion and achieving ideal performance metrics.

Simple Kiln Structure: The single-shaft vertical kiln design uses standard refractory bricks, making construction and maintenance easier compared to other kiln types. The beam burner system ensures stable lime quality, high activity, low energy consumption, and compatibility with multiple fuels. With simple equipment, high operational flexibility, small footprint, and relatively low investment, it is praised by users as a “trouble-free” kiln.

Mature Technology for Pulverized Coal + Gas Combustion: Many manufacturers lack gas as a fuel source. Based on years of operational experience, our company has successfully applied pulverized coal in vertical lime kilns. We have developed valuable expertise and technical know-how in precise coal powder measurement and efficient combustion within the kiln.