High-Temp Fuel Lances for Regenerative lime Kilns | 33-Outlet Uniform Distribution

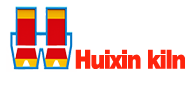

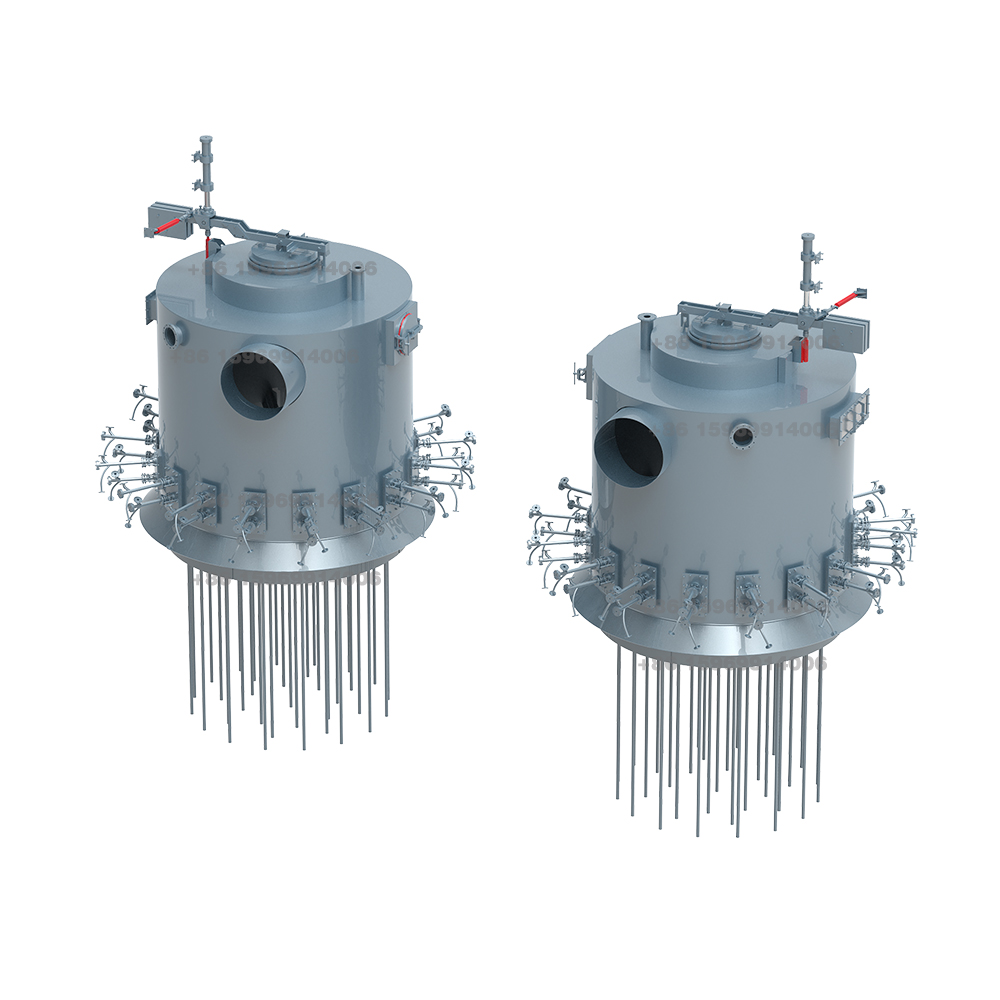

The fuel injection system is implemented by suspending lances from the kiln walls. These lances are uniformly mounted on the steel plates of the kiln walls, ensuring an even distribution of fuel injection outlets across the entire kiln cross-section. A single kiln chamber incorporates 33 uniformly spaced lance outlets, achieving homogeneous fuel distribution throughout the kiln’s cross-section. This configuration guarantees uniform temperature distribution across the kiln’s transverse plane, serving as a critical measure to ensure premium product quality.

The lances are secured using specially designed lance brackets welded to the kiln’s steel structure, which also serve to protect the lances. The lower sections of the lances are embedded in the limestone material, extending down to the base of the preheating zone. Under normal operating conditions, temperatures at the bottom of the preheating zone reach 800°C, necessitating the use of heat-resistant steel for the lances. Additionally, the exterior of the lances is coated with wear-resistant and thermal insulation materials, significantly extending their service life. Notably, the pulverized coal flowing through the lances provides a cooling effect during operation. When the kiln operates in heat storage mode, cooling air is circulated through the lances in that chamber to maintain temperature control and protection. The longevity of the lances is fully ensured, with a guaranteed service life exceeding 2–3 years.

**Key Features:**

– Uniform fuel/temperature distribution via 33 lance outlets

– Heat-resistant steel lances with protective coatings

– Integrated cooling mechanisms (coal flow + forced air)

– Structural integration with kiln framework

– Maintenance-friendly design for long-term reliability