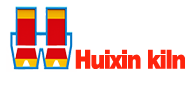

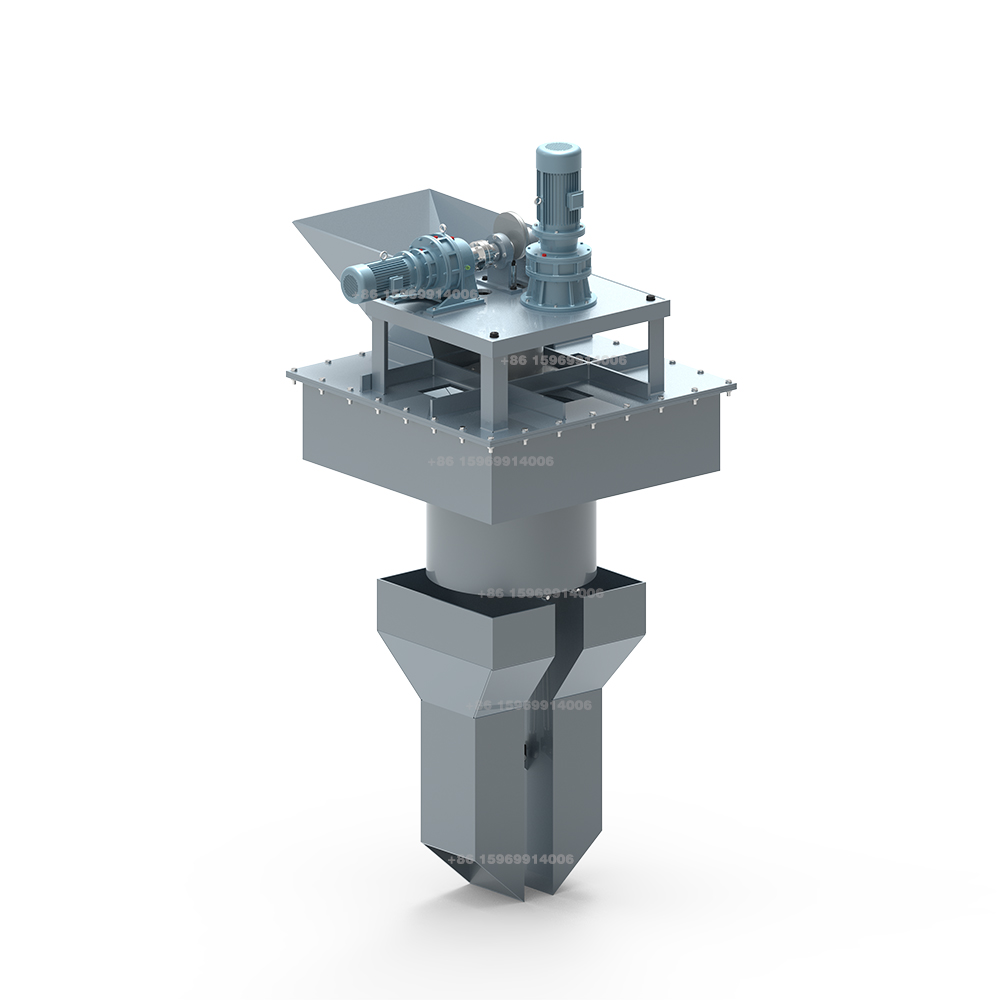

Uniform Material Distributor for Shaft Lime Kilns-Lime Kiln design

Distributor in Environmental Shaft Kilns

The distributor is one of the key pieces of equipment in environmental shaft kilns, primarily used to evenly and rationally distribute raw materials such as limestone inside the kiln, ensuring the stability and efficiency of the calcination process. It serves as an important device connecting the raw material conveying system and the kiln body, directly impacting the calcination effect and product quality of lime.

Main Functions of the Distributor:

- Uniform Distribution: Evenly distributes limestone raw materials inside the kiln, avoiding local accumulation or voids, and ensuring uniform heat distribution during calcination.

- Adjustable Distribution Mode: Adjusts the thickness and method of material distribution based on raw material characteristics and process requirements to optimize calcination results.

- Improved Calcination Efficiency: Reduces raw material waste and enhances thermal energy utilization through rational distribution, lowering energy consumption.

- Adaptability to Multiple Raw Materials: Capable of handling limestone raw materials with different particle sizes, moisture levels, and compositions, offering strong adaptability.

Working Principle of the Distributor:

The distributor is typically installed at the top of the shaft kiln, distributing raw materials evenly from the center to the periphery through rotational or reciprocating motion. Its working process is as follows:

- Raw materials enter the distributor’s feed inlet through the conveying system.

- The distributor evenly spreads the raw materials across the kiln’s cross-section through rotation or oscillation.

- The speed and angle of the distributor can be adjusted according to process requirements to achieve optimal distribution results.