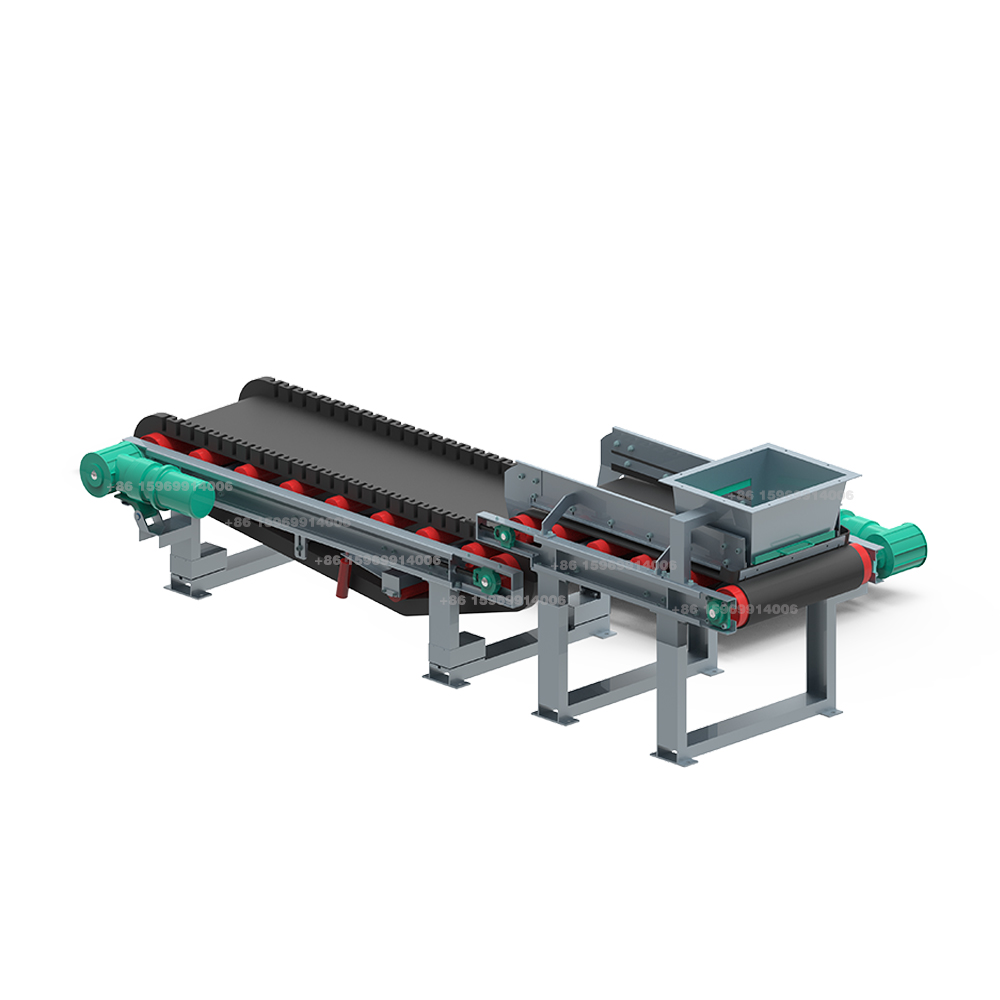

Coal Weighing and Batching Machine

Primarily used for precise weighing of coal fuel and proportional mixing with other raw materials to ensure accurate fuel ratio during calcination. It serves as a key equipment for achieving efficient combustion, reducing energy consumption, and minimizing pollutant emissions, directly impacting the stability of lime calcination, product quality, and environmental performance.

Working Principles:

- Feeding Stage:

- Coal is transported into the weighing bin via a conveyor belt or vibrating feeder.

- Weighing sensors measure the coal weight in real time and transmit data to the control system.

- Precision Weighing:

- Utilizes high-precision weighing sensors for real-time monitoring, with an error margin controlled within ±0.5%.

- Supports continuous multi-batch weighing to ensure uninterrupted and stable fuel supply.

- Ratio Calculation:

- The control system calculates the required addition of other materials (e.g., coal-to-limestone ratio) based on preset fuel-to-raw-material ratios.

- Mixing and Conveying:

- Weighed coal is mixed with other raw materials using a mixer or conveyor belt.

- The homogenized mixture is evenly fed into the calcination zone of the vertical kiln, ensuring complete combustion and uniform heat distribution.

- Closed-Loop Feedback:

- Kiln sensors monitor combustion parameters (e.g., CO concentration, temperature) and feed data back to the control system for real-time ratio adjustments.