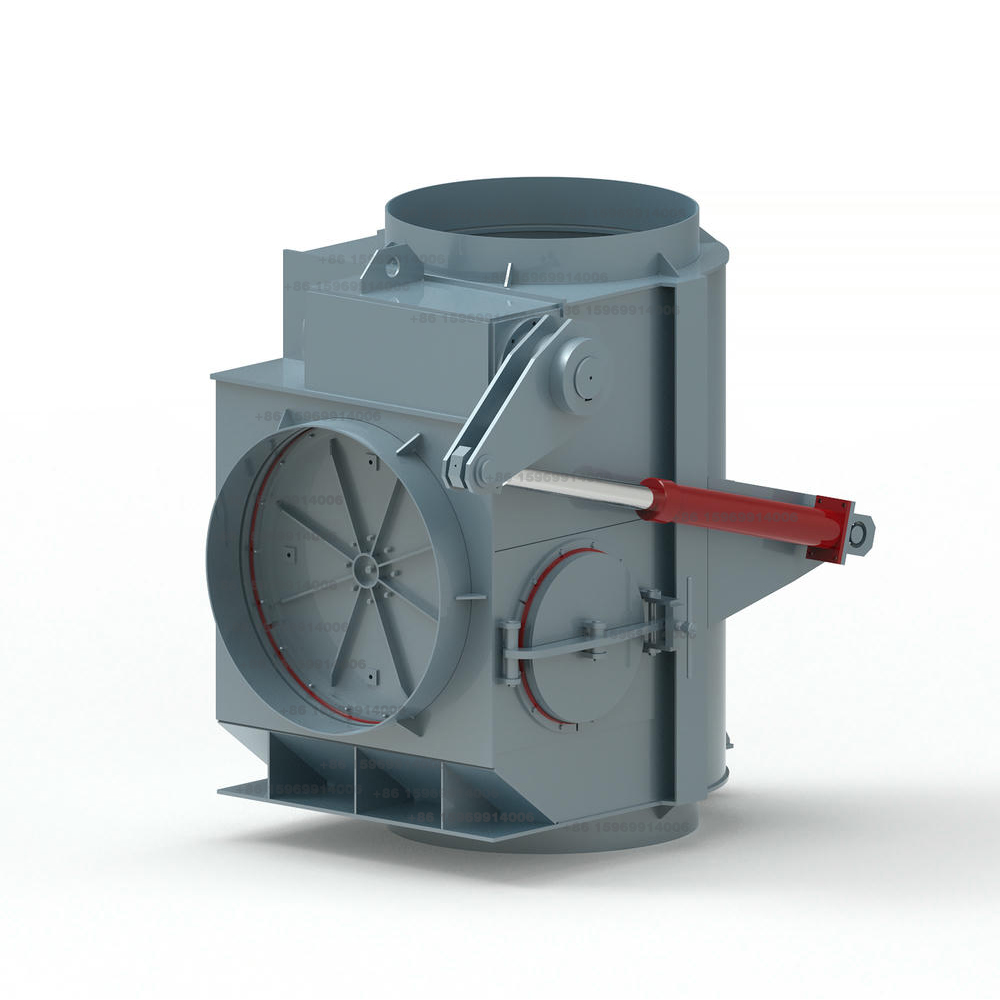

(Core Equipment of regenerative lime kiln)Reversing Valve

As the core control system of the calcination process in a regenerative lime kiln,the reversing valve enhances fuel efficiency by up to 40% through precise airflow direction switching between dual kiln chambers. Fabricated with heat-resistant alloy casting and equipped with servo motor drive system, it achieves 0.1-second switching accuracy under 800℃ operating conditions. The proprietary ceramic sealing assembly ensures zero leakage during 12-minute cycling intervals, while the integrated intelligent temperature control system enables ±2% dynamic adjustment of combustion medium flow.