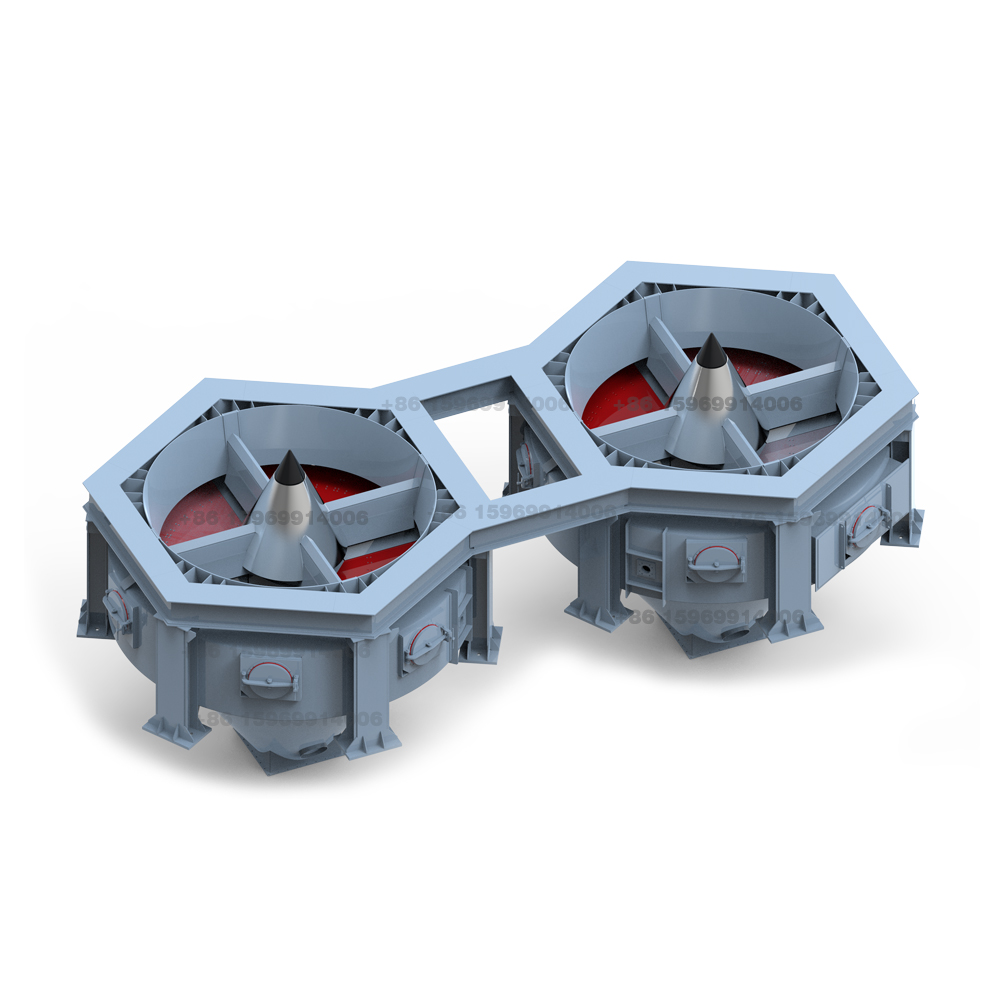

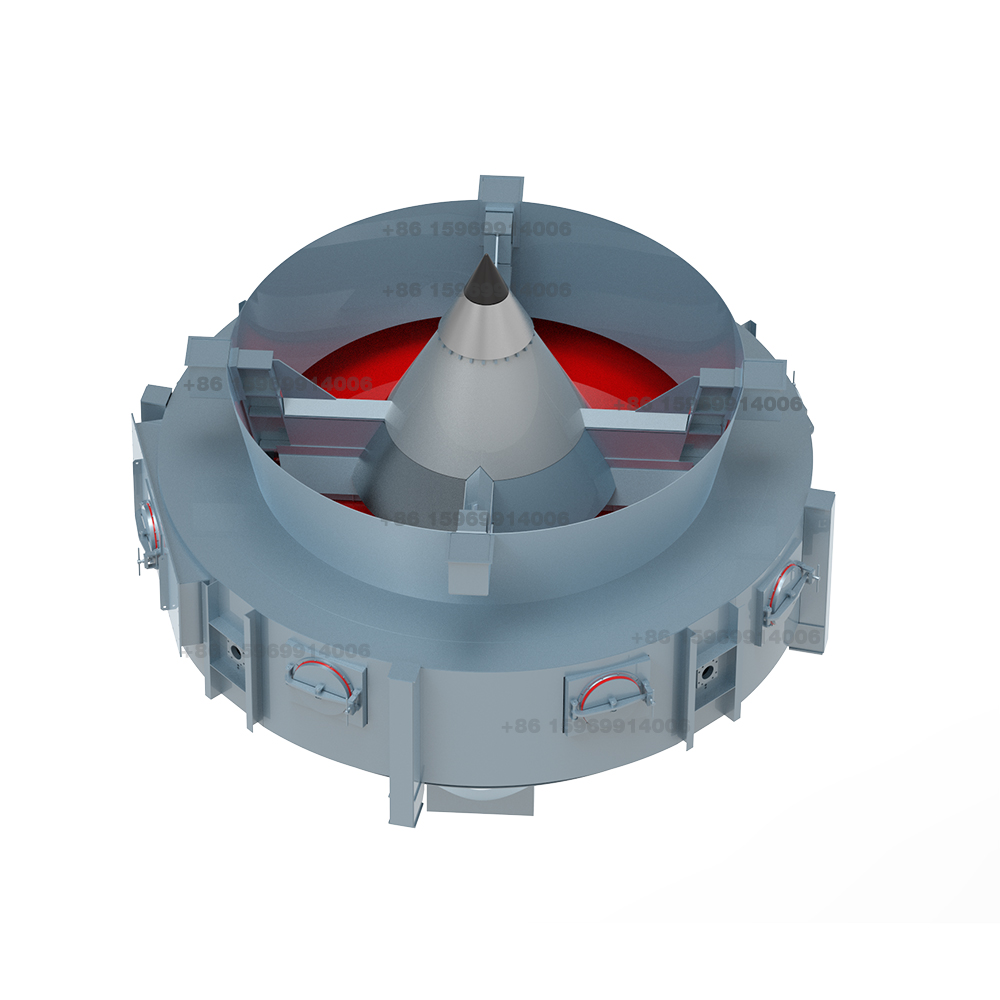

Lime Discharge System- Lime Kiln Equipment manufacturer

Function & Role

The lime discharge system is a critical component of the regenerative lime kiln, designed to efficiently and stably extract calcined lime from the kiln bottom and transfer it to cooling or storage processes. Its precise operation ensures balanced internal pressure and continuous combustion, preventing temperature fluctuations or blockages caused by uneven discharge.

Technical Features

- Automated Control

– Integrated PLC synchronizes with the kiln’s main control system, enabling timed/quantitative discharge or dynamic adjustment modes.

– Monitors real-time material levels and temperature to automatically optimize discharge speed, maintaining consistent bed height.

- High-Sealing Performance

– Multi-stage air-lock structure + high-temperature-resistant seals minimize air leakage and preserve thermal efficiency.

– Fully enclosed conveying channels with dust extraction ports to prevent emissions.

- Wear & Heat Resistance

– Critical components (e.g., ash discharge valve, screw conveyor) withstand extreme temperatures ≥1000°C and resist lime abrasion in harsh kiln environments.

– Modular design allows rapid replacement of wear-prone parts.

- Integrated Cooling

– Optional air/water cooling systems reduce lime temperature to a safe handling range (<80°C).

Value Proposition

– Ensures continuous kiln operation and improves product consistency.

– Reduces manual cleaning frequency, lowering maintenance costs and safety risks.