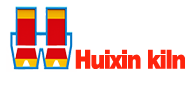

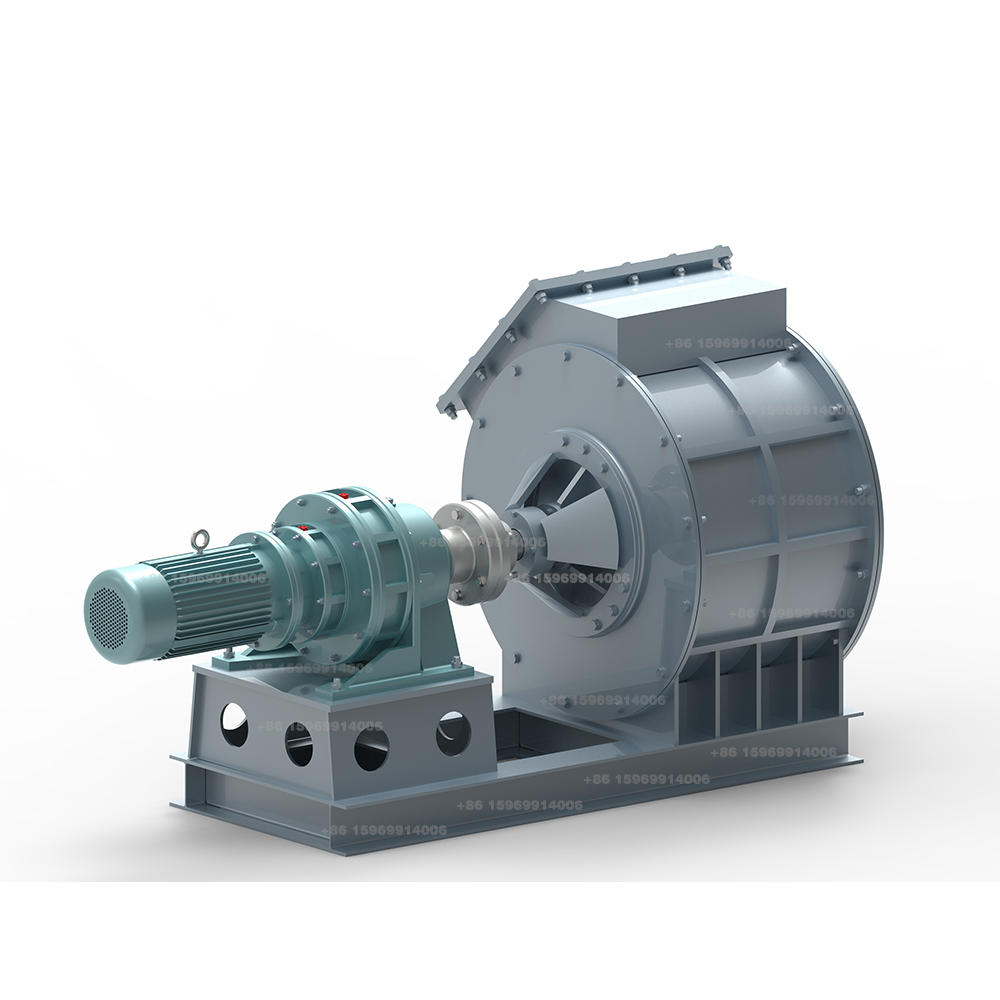

Star-Type Rotary Ash Discharge Valve (Environmental Vertical Kiln Equipment)- Quicklime production kiln

Star-Type Rotary Ash Discharge Valve (Environmental Vertical Kiln Equipment)- Quicklime production kiln

The Star-Type Ash Discharger (also known as Star Valve or Rotary Ash Discharge Valve) is a critical discharge device in environmentally friendly vertical kilns. It is designed to continuously, uniformly, and hermetically discharge calcined lime products from the kiln while maintaining stable internal negative pressure, preventing heat loss and dust leakage. Its high efficiency, energy-saving performance, and low failure rate make it an indispensable component of modern eco-friendly vertical kilns.

Core Features:

- Continuous and Stable Discharge:

- Utilizes a rotating star-shaped rotor to achieve uniform and uninterrupted discharge of calcined lime, preventing blockages or material interruptions.

- Adjustable discharge capacity (10–200 t/h) to meet varying production demands.

- Leakage-Proof Sealing:

- Multi-layer sealing structures (e.g., mechanical seals + graphite packing) ensure no leakage of high-temperature gases, with dust emissions <10 mg/m³.

- Maintains kiln negative pressure, reducing heat loss by 5%–10% and enhancing energy efficiency.

- High-Temperature and Wear Resistance:

- Rotor blades and housing are made of heat-resistant alloy steel or ceramic-lined materials, withstanding temperatures up to 400–600°C, tripling service life.

- Automated Control:

- Integrated with DCS/PLC systems to monitor discharge speed, temperature, and other parameters in real time, automatically adjusting rotor speed to adapt to production fluctuations.