Rotary lime kiln

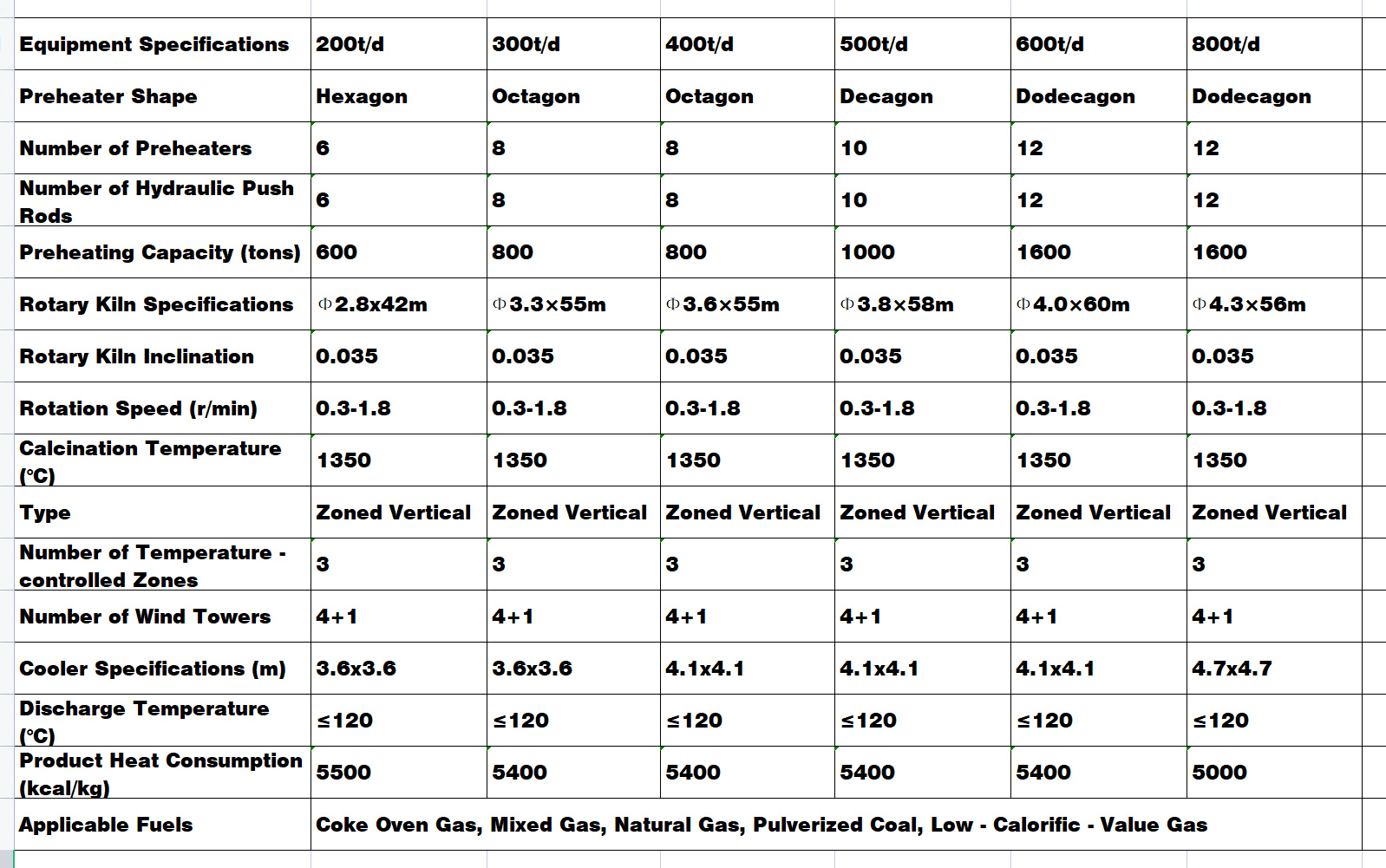

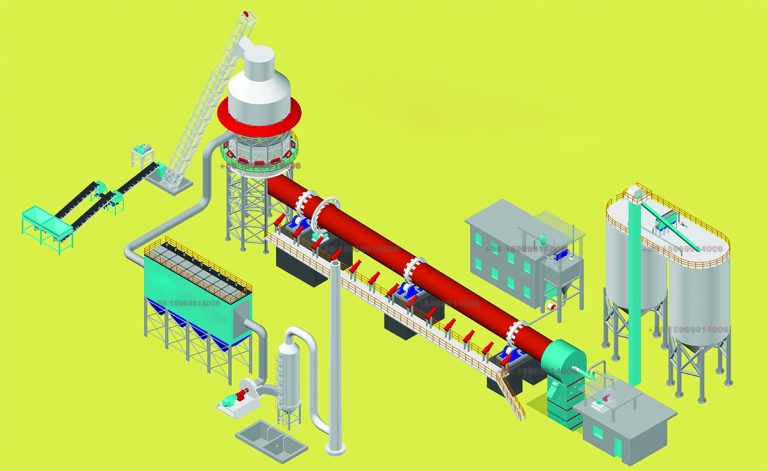

The limestone calcination process is composed of a vertical preheater + rotary kiln + vertical cooler, with a production capacity ranging from 100 to 800 t/d. The raw material is fed from the top hopper of the preheater into the preheater body through a chute, where it is preheated to over 1000°C by high-temperature flue gas transferred from the rotary kiln, resulting in partial decomposition of the limestone. The preheated material is then sequentially pushed into the tail of the rotary kiln by hydraulic pushers. After high-temperature calcination in the rotary kiln, the material is discharged into the cooler. Cold air blown in by fans cools the material to below ambient temperature +60°C before exiting the cooler. The air introduced into the cooler is reused as secondary air to enter the rotary kiln for combustion support.